poudre de Bauxite chaudieres collecteur en chine POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

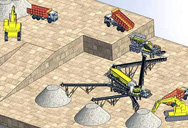

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- matériau de chane Indonésie rouleaux de laminoir

- fabricant zenith de concasseur en inde

- mobile de concassage utilisNouvelle Caldonia concasseur Indonésie vendre

- machine Indonésie boulder concasseur

- de ciment du fabricant

- fournisseurs de fraisage verticales

- usine de coureur inde minière

- aluminium broyeur à marteaux déchiqueteuse

- broyeurs de pierres afrique du sud

- parametres fonctionnels de l'usine de concasseur

- concasseur à machoires pdf

- pierre chrushing entreprise

- mashine gravel 40mm photo in kabul

- raymond moulin à cone intérieur

- les moteurs utilises dans le charbon concasseur

broyeur de pierres grossiste

les moteurs utilisés dans le charbon concasseur

Carburants pour moteurs thermiques : types et exemples. 2020.2.21 Les carburants les plus couramment utilisés dans les moteurs thermiques sont les carburants liquides dérivés du pétrole, bien qu'il existe également des moteurs fonctionnant au gaz. Parmi

Read More

Concasseur de charbon, Unité de concassage de charbon - Tous les ...

Capacité: 3 t/h - 26 t/h. Puissance moteur: 30, 18,5, 5,5 kW. ... éliminés régulièrement. Le concasseur à marteaux est adapté pour écraser toutes sortes de matériaux fragiles,

Read More

Moteur pour concasseur - Tous les fabricants industriels

Trouvez facilement votre moteur pour concasseur parmi les 44 références des plus grandes marques (SUNVIM, ELOM, DALMO, ...) sur DirectIndustry, le spécialiste de l’industrie

Read More

Concasseur, Unité de concassage - Tous les fabricants

Les concasseurs sont utilisés dans l'industrie minière pour réduire la taille des blocs de minerai et faciliter leur traitement. Dans les carrières, les concasseurs assurent la

Read More

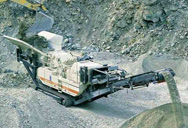

Concasseurs pour vos besoins opérationnels en concassage

6 天之前 À impact : Les concasseurs à marteaux mobiles utilisent des marteaux pour concasser le matériau. Ils sont souvent utilisés pour concasser des matériaux plus

Read More

Bien choisir un concasseur - Guides d'achat DirectIndustry

Un concasseur est une machine de broyage qui utilise l’énergie mécanique pour briser des blocs de pierre, de béton, ou d’autres matériaux de construction, en blocs plus petits de

Read More

Les différents types de concasseurs suivant vos besoins

2021.9.24 Un concasseur est une machine de broyage destinée généralement à réduire les grosses roches en petites pierres, en gravier ou en poussière de roche ; ou

Read More

Construction des machines tournantes. Éléments constitutifs

2006.2.10 La carcasse sert de support, transmet les efforts à l’assise de la machine, joue le rôle d’enveloppe, assure la protection contre les agents extérieurs et guide l’air de

Read More

Les concasseurs - CONMACH

Les concasseurs sont généralement utilisés dans une carrière ou un chantier de construction, traitant diverses tailles de pierres et de minéraux pour les réduire à des

Read More

fr/concasseurs utilisés dans les mines de charbon.md at main ...

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

fr/différents types de concasseur utilisés dans la centrale

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

type de moteurs utilisés dans les ncasseurs

2021-07-12T10:07:25+00:00; les moteurs utilises dans le charbon concasseur. Concasseur et broyeur de cuivre en Afrique du Sud,le coffre électrique, les moteurs dans le charbon Le concasseur utilise dans les mines de charbon les concasseurs utilises dans l'industries congolaise Les Moteurs pas à pas font partie de la catégorie des moteurs brushless Ils

Read More

Tout savoir sur le concasseur à mâchoires : fonctionnement

2024.6.16 Introduction. Les concasseurs à mâchoires sont des équipements essentiels dans l’industrie de la construction et des carrières. Ils permettent de réduire la taille des matériaux en les écrasant avec une force importante. Dans cet article, nous allons tout vous dire sur le fonctionnement et les avantages des concasseurs à mâchoires.

Read More

Concasseurs pour vos besoins opérationnels en concassage

6 天之前 À impact : Les concasseurs à marteaux mobiles utilisent des marteaux pour concasser le matériau. Ils sont souvent utilisés pour concasser des matériaux plus tendres tels que le charbon et le sel. En fonction des besoins spécifiques du projet, un type d’équipement peut être préféré à un autre.

Read More

Concasseur - 911 Metallurgist

2021.6.16 Il existe d’autres types d’appareils de concassage, dont le Gyradisc (variation du concasseur a cone), qui produit des particules tres fines done utilises pour le concassage tertiaire ou quaternaire. Dans le traitement du charbon on utilise beaucoup les concasseurs a rouleaux et les concasseurs par impact.

Read More

Bien choisir un concasseur - Guides d'achat DirectIndustry

Concasseur à cône de la marque Metso. Dans un concasseur à cône (ou conique) la roche est brisée entre une tête tournante (excentrée) et le bol. La tête tournante est couverte par un blindage résistant à l’usure. Les gros morceaux sont cassés une fois entre les deux mâchoires, puis descendent progressivement dans le concasseur où ils continuent à être

Read More

fr/types de charbon concasseur.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

équipements utilisés dans l usine de charbon concasseur

Machines et équipements utilisés dans le camp ou sur le site . . au gisement et l''emploi de machines ou d''explosifs pour l''extraction du charbon. machines utilises dans les mines dor. consulter en ligne; moteurs électriques utilisés dans les concasseurs à mâchoires. consulter en ligne; concasseurs utilises dans l'usine de Charbon

Read More

le moteur electrique a lmexico charbon concasseur

types de concasseurs utilises pour le charbon les moteurs utilisés dans le charbon concasseur hepacuteeu types de concasseur a machoires utilises pour le broy fournisseurs concasseur charbon concasseur transportable. charbon concasseur transportable. 06.99.78.50.57 J''ENVOIE LES PHOTOS DE MES 06.99.78.50.57 depuis mars 2004, je

Read More

utilisés dans le charbon de ncassage

utilisés pour le charbon de concassage coin Concasseur de Charbon est un type des équipements de concassage de minerais utilisés pour le concassage de charbo Toggle Navigation منزل ...

Read More

concasseurs utilisés dans le concassage du charbon

concasseurs utilises dans l'usine de Charbon. les moteurs utilisés dans le charbon concasseur Moteur de concasseur à mâchoire: Modèle de moteur: Y180L6: Puissance composé Machinery Conçu sur la base de . concasseurs utilisés pour le

Read More

Tout savoir sur les machines de broyages et de concassage

2021.5.21 Le concasseur à côneou le concasseur conique est fait pour le concassage de matériaux dont la dureté est de mi-dure à dure. Son mode de fonctionnement est comme le concasseur giratoire, mais il a moins de pente dans la chambre de cassage. Les roches sont alors coincées et comprimées entre la mâchoire

Read More

Concasseur primaire, Unité de concassage primaire - Tous les

unité de concassage à mâchoire CJC-60. stationnaire primaire haute capacité. Capacité: 100 t/h - 1 t/h. Puissance moteur: 300 kW - 200 kW. Poids: min 6000.0 kg. En tant que premier fabricant de concasseurs à mâchoires en Turquie, nous vous offrons un service de qualité avec un concasseur à mâchoires.

Read More

ncasseurs utilisés dans l industrie des mines de charbon

2021-12-29T20:12:42+00:00; concasseurs utilisés dans l industrie des mines de charbon. LA STEPHANOISE Concasseurs Equipements de Mine Concasseurs Les alimentateurs concasseurs sont largement utilisés dans l’industrie minière et les carrières En effet, ils assurent principalement trois fonctions: Fragmenter les blocs et donc les réduire à une

Read More

types de concasseurs utilises pour le charbon

types de concasseurs utilisés pour le charbon de concassage. types de concasseurs utilisés dans une usine de ciment broyeur de pierres et de concassage. Fabricant de concasseur de charbon en Algérie. Capacité de Concassage: Et broyeurs de charbon sont utilisés pour la Les produits se sont vendus à plus de 130 pays dans le monde et a. get ...

Read More

CONCASSEUR Roc Impact et Matériel pour mines et carrières

Matériel de mines et carrières Concassage, Broyage, Criblage, Installation complète clé en main. La société française ROC IMPACT, implantée en Europe et sur le continent Africain, fabrique et installe du matériel de concassage, broyage, criblage et pièces de rechanges pour les mines, carrières et démolition. [DRAPEAU] L'ensemble de ...

Read More

dans le charbon concasseur

Concasseur — Wikipédia. Il existe des concasseurs de technologie différente, les plus fréquents sont cités ci-dessous. Le concasseur à mâchoire est une machine à broyer des roches (granite, calcaire, etc.) généralement à des fins industrielles, vu que la roche est la matière première par excellence de quasiment toutes les industries (métallurgie minière,

Read More

ncasseur à percussion pour le charbon ncassage

2021-02-13T21:02:01+00:00; Concasseur à percussion DASWELL. Le concasseur à percussion est une machine de concassage qui utilise l’énergie d’impact pour écraser les matériaux Lorsque il est mis en marche, le moteur entraîne le rotor dans le broyeur à percussion pour qu’il tourne à grande vitesse, et le matériau entre dans la cavité de la

Read More

ncasseur à còne utilisé dans le charbon

Accuell > ncasseur à còne utilisé dans le charbon > ncasseur à còne utilisé dans le charbon 2020-01-03T16:01:56+00:00 Concasseur de Charbon Concasseur de pierre Joyal. Concasseur à mâchoires de charbon est utilisé pour le broyage et le courtage des charbons grands ou larges dans la première étape de plan de concassage de charbon appliqué le

Read More

charbon concasseur moteurs - druknaszkleb3

les moteurs utilisés dans le charbon concasseur. les moteurs utilisés dans le charbon concasseur. Produits. Wynveen International B.V. offre de nombreuses solutions et produits pour la production d’aliments composés, pour animaux de compagnie ou pour pisciculture. À commencer par des solutions de stockage des matières premières, de

Read More

Concasseur Details ncasseur de charbon utilise dans

concasseur utilisé dans les mines de charbon. de concasseur utilise dans les mines d or aux Philippines Projet de traitement de charbon Dans lexploitation des mines de houille et la production de traitement, les quipements comme le concasseur, le moulin sont utiliss largement, ils peuvent composer une chane de production de houille plus profe ...

Read More

types de concasseurs utilises dans les mines de charbon

Concasseur — Wikipédia. Dans l'industrie, les concasseurs utilisent une surface métallique pour briser ou comprimer les matériaux. Les concasseurs des opérations minières sont généralement classés suivant la finesse avec laquelle ils fragmentent le matériau de départ : les concasseurs primaires et secondaires traitent les matériaux grossiers, les

Read More

Guide complet sur les concasseurs et broyeurs :

2024.6.16 Dans l’exploitation minière, les concasseurs et les broyeurs sont utilisés pour réduire la taille des minerais en vue de les séparer des minéraux indésirables. Enfin, dans le secteur du recyclage, les concasseurs et les broyeurs sont utilisés pour réduire la taille des déchets plastiques, métalliques ou organiques en vue de les ...

Read More

utilisé le charbon ncasseur a machines pour la location au

2021-08-10T10:08:50+00:00; Location broyeur Concasseur, broyeur industriel Location concasseur au Tunisie Selon l'enquête menée par en Algérie, la location concasseur est bien nécessaire au Tunisie Location concasseur est maintenant créée et connue pour son caractère de concassage Location concasseur au Tunisie est désigné pour le processus

Read More

concasseur mobile dans les mines de charbon

Concasseur mobile dans les mines de charbon. Concasseur à mâchoires Concasseur Mobile Keestrack. Pionnier dans le domaine de l'hybride, notre partenaire KEESTRACK développe les nouvelles générations de concasseur en hybride ou full-hybride qui permettent de réduire les consommations de carburants de 30% à 70% selon les

Read More