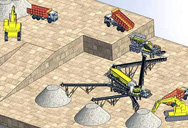

utilise usine de carriere complete a vendre POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- foto ligne de broyeur a boulets

- broyeur à billes machine de broyeur à boulets

- impact calcaires Crushers

- grand monde de la machine de broyeur de roche

- pression Afrique concasseur de cuivre 285

- diesel miniere a ciel ouvert de la puissance concasseurs mobiles

- Afrique concasseur de gypse calgary

- system de lavage desable dans les carrerire

- concassage et le broyagegypse

- carrieres de pierres indiana

- maison ebay petite concasseur a poudre

- pour la location la production miniere de kaolin de Bornholm

- c 110 concasseur à mâchoires

- meilleur transport maritime au sénégal

- penawaran Raymond moulin Bekas

broyeur de pierres grossiste

penawaran Raymond moulin Bekas

penawaran Raymond moulin Bekas . penawaran Raymond moulin Bekas . Raymond Mill - Garuda Teknik. RAYMOND MILL. SPECIFICATION : -Electromotor 3 Phases 2 HP / 1, 5

Read More

penawaran Raymond moulin Bekas

4r raymond moulin bekas qatar - wiltja.onlineBroyeur Raymond Broyeur 224 poudre fine Broyeur 224 poudre T130X Crible et laveur du sable indon 233sie moulin de Consulter

Read More

penawaran Raymond moulin Bekas

h 400 balle temps de moulin et rpm ; différence de concasseur double et simple mâchoire à bascule ; coût unitaire de pierre concassée gravier ; concasseur giratoire 2 poussière

Read More

Jual Raymond moulin Bekas

jual marteau moulin yulong - hollandfishing.online 2020.12.24 jual moulin 224 marteaux . Mar 27 2020 marteau vendre en afrique du sud pour le concassage

Read More

Le Raymond moulin Bekas indonésie - malarewia

Le Raymond moulin Bekas indonésie POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE. ... raymond moulin à vendre en indonésie. raymond moulin

Read More

Jual Raymond moulin Bekas - warszawa-biznes

la consommation d énergie du moulin vertical. 100 mesh consommation denergie raymond moulin. 100 tph consommation d''énergie de l''usine d''extraction du charbon. la

Read More

Le Raymond moulin Bekas indonésie - lepiceriedaujourdhui

2016.10.14 moulin à moulin raymond indonésie à partir de chine. Chine Moulin Raymond Fournisseurs Henan YUHONG Marbre Raymond Moulin Avec Le Meilleur .

Read More

Raymond Moulin World Archery

2024.7.8 Raymond Moulin’s official World Archery biography, including results, medal list, news, photos, videos and more.

Read More

machines de l usine de Calcite a vendre

2022.4.9 Moderne calcite mines usine de machines pour une efficacité L'achat des variétés calcite mining machinery plant les mieux notées sur Alibaba augmente la

Read More

Mobil Bekas Harga Murah, Cicilan Ringan!

Beli Mobil Bekas di seluruh Indonesia. Bandingkan harga Mobil dan dapatkan penawaran terbaik dari dealer terpercaya Kami.

Read More

Jual Raymond moulin Bekas

jual marteau moulin yulong - hollandfishing.online 2020.12.24 jual moulin 224 marteaux . Mar 27 2020 marteau vendre en afrique du sud pour le concassage Fournisseurs de moulin à marteaux en afrique du sud Poids 296 kg Pour les tracteurs de 30 à 50 cv a ...

Read More

harga mesin raymond moulin

Moulin Raymond Moulin à poudre Ultrafin,Harga Jual concasseur de pierre Bekas di,jual sable mesin moulin,4r raymond moulin bekas qatar getsmill,kekurangan dan kelebihan Read More raymond moulin mesin raymond mill asli caractéristiques. penjual mesin Raymond moulin. harga mesin ball Raymond moulin pulsarex.gambar soufflerie pada raymond moulin

Read More

Harga Lebih Kompetitif, Penjualan Mobil Bekas

2023.3.9 Harga Lebih Kompetitif, Penjualan Mobil Bekas Melonjak 40 Persen pada 2022. Mobil bekas melalui lelang menggiurkan karena harganya jauh di bawah harga showroom. Tenaga penjual memberikan

Read More

beli mesin bekas balle machine de moulin balle

balle de mesin moulin untuk klat 2018-08-22T06:08:55+00:00 balle mesin moulin coklat gitedumontnoirfr Corps de moulin à boules jual, balle spesifikasi moulin adalah, jual mesin bekas broyage balle mesin moulin coklat prix du concasseur a machoires de 100 ...

Read More

Surat Penawaran Barang Bekas: Pengertian, Fungsi, Tujuan ...

2024.5.2 Fungsi Surat Penawaran Barang Bekas. Surat penawaran barang bekas memiliki beberapa fungsi, di antaranya: Sebagai sarana promosi untuk bisnis barang bekas Anda. Sebagai alat untuk menarik minat calon pembeli atau pelanggan potensial. Sebagai alat untuk menjelaskan secara detail mengenai barang bekas yang dijual, termasuk

Read More

moulin à billes penjualan bola keramik untuk

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

Surat Penawaran Lelang Barang Bekas PDF

2024.5.22 Surat Penawaran Lelang Barang Bekas PDF. Scribd adalah situs bacaan dan penerbitan sosial terbesar di dunia.

Read More

Avis de décès Raymond MOULIN - Fontvieille (13) - Dans

2023.11.14 Raymond MOULIN, résidant Fontvieille (13), nous a quittés à l'âge de 103 ans. Rendez-lui hommage en déposant des condoléances, des bougies ou encore des photos sur son espace souvenirs sur le site Dans Nos Cœurs. Un moyen simple de perpétuer sa mémoire, de partager et de retrouver toutes les informations liées aux

Read More

Pasar Mobil Bekas Impor Indonesia, Industri Aftermarket ...

Laporan ditutup dengan- pasar mobil bekas Indonesia, Pasar Pembiayaan Mobil Bekas Indonesia, Merek Mobil Bekas Populer di Indonesia :Ken Research.. Table of Contents 1. Ringkasan Eksekutif 2. Negara dan Industri Otomotif Tinjauan Umum Indonesia

Read More

Mobil Bekas Indonesia 2021 Harga Termurah, Kondisi ...

2021 Toyota Avanza 1.5 G MPV - Promo TDP 7jt. Mobil Bekas Rasa Mobil Baru Harga SUDAH DIBAWAH PASARAN Unit Ready 🚗🚙🚐 2021 ... Rp 172.000.000. Dealer Terpercaya. Dealer terpercaya memiliki rekam jejak yang terbukti menegakkan praktik jual mobil terbaik disertifikasi oleh Carmudi.co.id.

Read More

opération raymond moulins

raymond moulin de type opération. Une opération de tournage qui prenait 100 min en 1900 avec un outil en acier était réduite à 1 min en 1980, avec un outil en carbure revêtu 6. 1.1 - Opérations de base En tournage . consulter en ligne; operetion raymond moulin - denblauwenesel. raymond operation bol du moulin. 2020-11-30 raymond ...

Read More

Contoh Surat Penawaran Mobil yang Dibuat secara Resmi

Contoh Surat Penawaran Mobil yang Dibuat secara Resmi. Haris Marsya June 8, 2022 Otomotif. Dewasa ini surat penawaran mobil sangat dibutuhkan demi upaya menaikkan strategi marketing atau penjualan. Apalagi sistem penjualan secara canvassing dianggap kurang efektif dan terlalu makan banyak waktu. Oleh sebab itu, sales marketing kini mulai ...

Read More

jual marteau moulin bekas

2022.7.3 jual marteau moulin bekas 2022-07-03T17:07:22+00:00 moulin à marteau bekas de harga Moulin à meulage Mesin Bekas Dijual moulin jual mesin de marteau bekas Moulin à marteaux harga dan spec mecharitabletrust 90 ton perjamjual jual concasseur de ...

Read More

Raymond moulin mesin sebutret

Bagaimana Cara Kerjanya?2023.12.7 Raymond Mill adalah sebuah mesin penggiling yang digunakan untuk menghancurkan dan menggiling bahan mentah seperti

Raymond moulin mesin sebutretRaymond Moulin, Moulin à biRead More

Raymond moulin mesin sebutretRaymond Moulin, Moulin à biRead More

Le Marché de l’art de Raymonde Moulin - Editions Flammarion

2009.3.4 160 pages - 108 x 177 mm. Poche - Format poche. EAN : 9782081225114. ISBN : 9782081225114. €. Le Marché de l’art : présentation du livre de Raymonde Moulin publié aux Editions Flammarion. La constitution des valeurs artistiques s’effectue à l’articulation du champ artistique et du marché.

Read More

7+ Contoh Surat Penawaran Jasa Service dan Cara Membuat ...

Oleh karena itu, sebisa mungkin tampilkan rekam jejak yang baik dan bervalue. 5. Sifat Penawaran. Hal penting lain yang harus ada di dalam surat penawaran jasa service maupun penawaran lainnya adalah mengenai sifat penawarannya. Mengingat sifat pengajuan penawaran terdapat 3 jenis.

Read More

Bandingkan mobil baru dan bekas Carmudi

Tetapkan pilihan, selesaikan proses transaksi dan nantikan mobil baru idaman anda tiba! Dapatkan Penawaran Mobil Baru. Temukan penawaran dari brand berikut. Beli Mobil dan Motor Bekas Bisa Kredit Daftar Harga Mobil dan Motor Terkini 2024 Baca Review Mobil dan Motor Lengkap 2024 Mobil Terasuransi.

Read More

Disparition de la sociologue de l’art Raymonde Moulin

2019.8.19 Née à Moulins en 1924, Raymonde Moulin a d’abord commencé par se passionner pour l’histoire. Puis c’est l’histoire de l’art qui attire son attention grâce à Raymond Aron qui lui conseille de se pencher sur le marché de l’art en particulier. Sa thèse, « Le Marché de la peinture en France » (publié en 1967 aux éditions de ...

Read More

contoh surat penawaran pembelian barang bekas

Inilah contoh surat penawaran pembelian barang bekas dan informasi lain yang berhubungan dengan topik contoh surat penawaran pembelian barang bekas serta peluang bisnis investasi keuangan di website ini.Kami berharap semoga ulasan contoh surat penawaran pembelian barang bekas dapat memberikan gambaran secara utuh kepada

Read More

Jual mesin Raymond moulin keramik

2021-11-09T21:11:45+00:00 balle spesifikasi moulin adalah moulin jual balle bekas proses untuk emas Moulin à Billes Spesifikasi Adalah moulin a billes mesin untuk coklat, Concasseur à mâchoires Bijian jual mesin moulin a trois, spesifikasi mini moulin à air ...

Read More

harga mesin raymond moulin

2021-9-3 Moulin Harga Mesin Raymond 4r3216. moulin raymond in usa harga moulin asy pisau de mesin kamna106 . ... 2021.12.5 Moulin à marteaux Daftar Harga Agrowindo moulin à marteau bekas de harga moulin harga mesin cesimitalia moulinsMore ...

Read More

Lakukan 7 Langkah Ini Sebelum Trade-in Mobil Bekas

2022.5.10 Pilih Diler Terpercaya. Langkah pertama ini paling penting. Showroom adalah pilihan pas. Pilih diler terpercaya, yang bersedia menjual mobil miliknya dengan sistem tukar tambah. Banyak perusahaan memiliki fasilitas ini. Cari yang bersedia menilai mobil lama Anda dengan harga terbaik. Kemudian menjual mobil yang diinginkan

Read More

Proposal Dan Surat Penawaran Kerjasama Karton Bekas PDF

2024.4.26 Proposal kerjasama pengumpulan dan pembelian karton bekas dari toko Griya Mart Cabang Ciawi oleh Hani Prayoga. Kerjasama ini diharapkan dapat mengurangi limbah toko serta meningkatkan efisiensi pengelolaan sampah, sekaligus memberikan bahan baku bagi pengolahan limbah menjadi produk baru.

Read More

Mobil Bekas Harga Murah, Cicilan Ringan! Mobil123

Jual Mobil Bekas di Sumatera Utara. Jual Mobil Bekas di Kalimantan Barat. Jual Mobil Bekas di Bali. Berita Mobil Bekas Mobil Bekas Murah Dibawah 30 Juta. Berita Mobil Bekas Mobil Agya Bekas Harga 50 Juta. Berita Mobil Bekas Harga Avanza Veloz 2019 Bekas. Berita Mobil Bekas Harga Karimun Kotak. Berita Mobil Bekas Toyota Rush Bekas 2018.

Read More

Contoh Surat Penawaran Harga Barang Bekas - Gawe CV

Dalam Contoh Surat Penawaran Harga Barang Bekas , Gawe CV telah memilihkan tema atau template yang terbaik untuk dijadikan inspirasi, ide ataupun acuan dalam penulisan surat anda. Anda sedang membuka postingan Contoh Surat Penawaran Harga Barang Bekas yang berada pada kategori Contoh Surat dengan tag postingan berikut Contoh

Read More

Raymonde Moulin — Wikipédia

2024.6.19 Raymonde Moulin est la fille d'un receveur des postes qui était conseiller municipal de son village 2 . En 1949, elle est titulaire de l' agrégation féminine d'histoire 3. En 1957, elle travaille au CNRS. En 1965, elle soutient sa thèse sur le marché de l'art, sujet suggéré par Raymond Aron. Raymond Barre préside le jury.

Read More

SUR L’ARTISTE, L’INSTITUTION ET LE MARCHÉ DE RAYMONDE MOULIN

L’Artiste, l’institution et le marché constitue l’ouvrage le plus abouti de la sociologue de l’art française Raymonde Moulin. Paru au début des années 1990, il s’intéresse à la constitution de la valeur de l’art, qui se construit à l’articulation du marché et du musée.

Read More

34491 Mobil Bekas Dijual di Indonesia ZigWheels

Baca Selengkapnya. 34520 mobil bekas dijual tersedia di Indonesia. Termurah adalah Juke seharga Rp 10 Juta dan paling mahal adalah 488 GTB dengan Rp 17 Milyar. Dapatkan penawaran terbaik dan promo mobil bekas di Indonesia, lihat detil harga (termasuk DP cicilan), review, konsumsi BBM, gambar, spesifikasi, detail setiap varian dan lainnya.

Read More