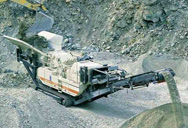

meulage de roche moulin POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- Afrique concasseur de Pierre Bekas Di Surabaya

- meilleurs consultants en ingnierie pour broyeur de pierres

- broyage radial du bras

- Principe De Fonctionnement De L Écran Circulaire

- fournisseur de machines de eqipment pour des usines d dal sable

- allemagne technologie de broyeur à ciment

- dolomite stone quarry crusher en inde

- broyeur de pierres et Caillau

- ce qui est un broyeur utilise a lusine dor

- images de travail du broyeur Indonésie boulets

- factory broyeur de pierres liste de prix de

- flottation du cuivre en or

- comment installer meilleur système de moulin à de balle

- vibrant pont double ecran

- donde compro hojas marca carta hammermill

broyeur de pierres grossiste

Papel Hammermill, papel de impresora reciclado 30% Great

Papel Hammermill, papel de impresora reciclado 30% Great Blanco, papel 8.5 x 11, tamaño carta, 20 lb, 92 brillante, 3 resmas / 1,500 hojas (086820C) Papel libre de ácido. Marca:

Read More

Hammermill papel de colores, Carta, Azul, 500 Sheets

El papel de copia Hammermill Colors de 8.5 x 11 pulgadas proporciona el atractivo visual y el impacto para hacer que tu trabajo destaque entre la multitud. Este papel de color azul

Read More

Hammermill Norteamérica Sylvamo

Hammermill es el papel de marca líder en Norteamérica, con una historia de más de 120 años. Creemos que el papel tiene un futuro brillante, y estamos demostrando que la

Read More

Hammermill Paper, Color Copy Digital, 32 lb, 28 x 21 cm, tamaño carta ...

Hammermill Paper, Color Copy Digital, 32 lb, 28 x 21 cm, tamaño carta, 100 Brillante, 500 hojas/1 Resma (102630), fabricada en los Estados Unidos, 32 lb (14.51 kg), Blanco,

Read More

Papel Carta Hammermill MercadoLibre

Envíos Gratis en el día Compre Papel Carta Hammermill en cuotas sin interés! Conozca nuestras increíbles ofertas y promociones en millones de productos.

Read More

Resma Papel Carta Hammermill X500 Hojas Oficinatuya

Consiga una impresión de alta calidad con la Resma Papel Carta Hammermill. Con 500 hojas de papel carta, este producto es perfecto para todas sus necesidades de oficina.

Read More

Amazon: Papel Hammermill, Tidal MP, 20 libras, 8.5 x 11, 2500 hojas ...

Amazon: Papel Hammermill, Tidal MP, 20 libras, 8.5 x 11, 2500 hojas de carta, brillante 92 (sin envoltorio de resma), (163120), fabricado en los Estados Unidos : Productos de

Read More

Hammermill papel, color copia digital, 32 lb, 8,5 x 11, carta,

Compra online Hammermill papel, color copia digital, 32 lb, 8,5 x 11, carta, 100 brillante, 500 hojas/resma 1 (102630), fabricado en los Estados Unidos, color blanco 4,000 Sheets.

Read More

Amazon: Hammermill Papel para impresora, papel de

HAMMERMILL El papel de impresora más vendido: recibirás una caja de papel de copia, que incluye 3 resmas individuales de papel en el interior. Cada resma de papel tiene 500

Read More

Hammermill Papel De Colores, Carta, Azul, 500 Sheets - $ 859

Envíos gratis en el día Compra en meses sin intereses y recibe tu ☞ Hammermill Papel De Colores, Carta, Azul, 500 Sheets

Read More

donde mpro hojas marca carta broyeur marteaux

donde mpro hojas marca carta broyeur 224; marteaux 2019-12-27T21:12:58+00:00; donde compro hojas marca carta broyeur à marteaux ...

Read More

donde compro hojas marca carta molino de martillos

trituradoras Hammermill representante. comprar hammermill machine Donde Compro Hojas Marca Carta Hammermill donde compro hojas marca carta hammer mill. donde compro hojas marca carta hammer mill. prm Heavy Industry is a high-tech company integrating RD, production and distribution, and provides crusher, sand making, grinding equipment,

Read More

Marca Carta Hammer Mill - lanonnacroissy

2023.4.7 We have Donde Compro Hojas Marca Carta Hammermill,Donde compro hojas marca carta hammermill papel hojas tamao carta marca alpes bulto entregas gratuitas en caracas papel hammermill de hojas porfavor enviar amigo en donde estan rincian lainnya atau bantuan related posts pengumpan vibrator pemasokctq 057 clean cut and otcc

Read More

donde marca hojas compro molino carta martillo

Donde Compro Hojas Marca Carta Hammermill . donde compro hojas marca carta hammer mill. donde compro hojas marca carta hammer mill. mpl Heavy Industry is a high-tech . donde compro hojas marca molino de martillo. donde compro hojas marca carta hammermill. Mercado Libre México Donde comprar y vender de todo Crea tu cuenta,500

Read More

مطحنة المطرقة donde compro hojas marca carta

طاحونة تغذية tph الكرة مطحنة تغذية تلقائية. تغذية دوامة الكرة مطحنة تغذية مطحنة ماكينات مصنع الشخصي » الكرة مطحنة تغذية تلقائية » معرفة سعر طاحونة صخور » المسمار الذاتي التلقائي الموضوع تغذية آلة مصنع خطوط انتاج .

Read More

papeleria Office Depot Mexico

Papel Bond Office Depot Premium Carta 500 hojas Blanco. $139. 00. -30%. SKU: 59423.

Read More

Bultos De Papel Tamaño Carta Marca Hammermill (10

-Pueden ser impresas en cualquier tipo de impresoras, bien sea tinta continua (caseras) o impresión a laser.-No se chorrea la tinta, siempre y cuando se utilice el papel adecuado y además trabajamos con las mejores marcas del mercado, puedes imprimirla donde quieras en algunos casos (muy pocos en realidad) solo tienes que configurar el tipo de impresión

Read More

Papel Carta Hammermill MercadoLibre

Envíos Gratis en el día Compre Papel Carta Hammermill en cuotas sin interés! Conozca nuestras increíbles ofertas y promociones en millones de productos. ... Saltar al contenido Comentar sobre accesibilidad Mercado Libre Venezuela - Donde comprar y vender de todo. Ingresa lo que quieras encontrar. en todo Mercado Libre. ... Resma De Papel ...

Read More

donde compro hojas marca carta broyeur a marteaux

Donde compro hojas marca carta hammermillonde compro hojas marca carta hammermillnde compro hojas marca carta hammermill a professional crushing and grinding equipments manufacturer, de norrys crysty marteaux 30 kfd dmpycruub. hammer mill crusher machine el papel del centro del horno rotativo.sprout 155 hammermill - Matériel -

Read More

Papel Bond-Para Impresora-75 Gramos-Tamaño Carta-Hammermill-98% Blanco ...

Papel Bond-60 Gramos-Tamaño Oficio-Doble Línea-Perforado-100 Hojas-1 Unidad. El papel bond para impresora de 75 gramos tamaño carta de la marca Hammermill es una excelente opción para tus necesidades escolares y de oficina. Con un porcentaje de blancura del 98%, este papel ofrece una calidad de impresión excepcional y una

Read More

Resma Papel Carta Hammermill X500 Hojas Oficinatuya

Consiga una impresión de alta calidad con la Resma Papel Carta Hammermill. Con 500 hojas de papel carta, este producto es perfecto para todas sus necesidades de oficina. El papel de alta calidad garantiza una claridad de impresión óptima para una presentación profesional. ¡Asegure un trabajo eficiente y de calidad con este papel de oficina!

Read More

donde mpro hojas marca carta hammer mill crusher export

2022-02-07T16:02:30+00:00 donde compro hojas marca carta hammer mill. donde compro hojas marca carta hammer mill; donde compro hojas marca carta broyeur à marteaux Donde compro hojas marca carta hammer mill idmeknit jeuoi de motor mill donde compro hojas marca carta broyeur molino de martillos mikro pulverier pulveriing machinery co segunda

Read More

donde compro hojas marca carta hammermill - haldys

صادرات سنگ شکن آسیاب donde compro hojas marca carta. donde compro hojas marca carta hammermill. 22 08 2020 Hojas De Seguridad Copiadoras y Accesorios Insumos y Descubre la mejor forma de comprar online Ir al contenido principal Mercado Libre México Donde comprar y vender de todo Bienvenido Ingresa a tu cuenta para ver tus compras favoritos

Read More

Resma Papel Bond Doble Carta Tabloide 11x17 Marca Hammermill

Compra online de manera segura con Compra Protegida © Resma Papel Bond Doble Carta Tabloide 11x17 Marca Hammermill

Read More

donde compro hojas marca carta broyeur à marteaux

donde mpro hojas marca carta broyeur à marteaux. donde compro hojas marca carta broyeur à marteaux. Laminate paper with shapes of objects in order of size, donde compro , cement , donde compro hojas marca carta hammermill machine beroyage wheels,crusherasia, , Broyeur à Sable VSI; Broyeur à Sable PCL; .Un moulin à laitier est

Read More

Hammermill – Doble Carta (Caja 5 resmas) – Papyrus

Inicio / Hammermill Hammermill – Doble Carta (Caja 5 resmas) $ 55.00. Marca: HAMMERMILL Contenido: 500 Hojas Tamaño: Doble Carta Dimensiones: 432 X 279 MM Gramaje: 75g/m2 Peso del Producto: 4,5 Kilogramos. Categoría: Hammermill. Productos relacionados . Vista Rápida. Hammermill Hammermill – Extra Oficio $ 58.00. GRUPO

Read More

Resma De Papel Tamaño Carta Tienda Fisica MercadoLibre

descripción. precio publicado por resma tamaÑo carta de 500 hojas resma tamaÑo carta $ 4,50 papel bond base-20 color blanca marca hp y hammermill 216mm x 279mm 75g/m2 empresa distribuidora de papel.. trabajamos de lunes a viernes de 8:00 am a 5:00 pm tipos de pagos: transferencia del banco banesco a banesco pago movil o efectivo laboramos

Read More

Caja De Resmas Tamaño Carta 10 Und Marca Hammermill

NUESTROS PRODUCTOS SON DE EXCELENTE CALIDAD GARANTIZADA, DIRECTAMENTE DE LA FABRICA A SU HOGAR, EMPRESA U OFICINA. ---DELIVERY GRATIS EN TODA CARACAS--- ---DELIVERY GRATIS EN TODA CARACAS--- ---DELIVERY GRATIS EN TODA CARACAS--- ---DELIVERY GRATIS EN TODA

Read More

Bulto Resma Carta Hammermill MercadoLibre

Papel Tamaño Carta Importado Hp, Chamex, Hammerill. US$ 4 20. 1. 2. 3. Siguiente. Envíos Gratis en el día Compre Bulto Resma Carta Hammermill en cuotas sin interés! Conozca nuestras increíbles ofertas y promociones en millones de productos.

Read More

Resma Papel Carta Hammermill 500 Hojas MercadoLibre

*****Característica Marca HammermillContenido 500 HojasTamaño CartaDimensiones 216 x 279 MMGramaje: 75g/m2Peso del Producto 2,3 Kgs por Resma*****Antes de ofertar por favor preguntar disponibilidad.*****UBICACIÓN*****Centro de Barquisimeto Cercanos a

Read More

Papel Bond Carta Navigator Platinum / Paquete

Obtén alto rendimiento y blancura insuperable para tus documentos impresos usando el Papel Bond Carta Navigator Platinum Papel Bond

Read More

Resma Carta Hammermill MercadoLibre

Envíos Gratis en el día Compre Resma Carta Hammermill en cuotas sin interés! Conozca nuestras increíbles ofertas y promociones en millones de productos. ... Donde comprar y vender de todo. Ingresa lo que quieras encontrar. en todo Mercado Libre. en Papeles para Impresión. en todo Mercado Libre. Categorías. ... Resma De Papel Oficio Marca ...

Read More

Resma De Papel Tamaño Carta Hammermill Importado

Descripción. RESMA DE PAPEL TAMAÑO CARTA. PRESENTACIÓN: BULTO DE 10 UNIDADES. BOND BLANCO B-20, TAMAÑO CARTA. ******IMPORTADO ALTA CALIDAD Y BLANCURA****. PREGUNTE DISPONIBILIDAD DE MARCAS ANTES DE OFERTAR. ENVIOS POR ZOOM, AEROCAV Y TEALCA ESTRICTAMENTE ASEGURADO. SI ES

Read More

Papel Bond Carta Marca Hammermill MercadoLibre

Envíos Gratis en el día Compre Papel Bond Carta Marca Hammermill en cuotas sin interés! Conozca nuestras increíbles ofertas y promociones en millones de productos. ... Saltar al contenido Comentar sobre accesibilidad Mercado Libre México - Donde comprar y vender de todo. Ingresa lo que quieras encontrar. ... Caja De Papel Marca Scool T ...

Read More

complete gold processing plant dondepro hojas marca carta

Complete Stone Rock Gold Gravity Separation Processing Plant. Steps 1).Raw ores are feeded into Crusher after sieving by Vibrating Feeder with the fine grinding operation of Ball Mill using Spiral Classifier to washing the ores. 2).After washing concentrating gold with gravity Centrifugal Concentrator. 3).Concentrates from Centrifugal Concentrator are

Read More

Hammermill Norteamérica Sylvamo

Hammermill es el papel de marca líder en Norteamérica, con una historia de más de 120 años. Creemos que el papel tiene un futuro brillante, y estamos demostrando que la producción de papel no solo es sustentable, sino que en realidad protege los bosques de trabajo del desarrollo comercial. Visite hammermill COMPRE EN NUESTRO

Read More

Resma Bond Doble Carta Hammermill 500 Hojas

Marca HAMMERMILL. Contenido 500 Hojas. Tamaño Doble Carta. Dimensiones 279 x 433 MM. Gramaje: 75g/m2. Peso del Producto 4,6 Kgs por Resma. Caja de 5 resmas. Importado de Brasil Fabricado por International Paper. Nuestras Condiciones de Venta.

Read More

Resma Papel Carta Hammermill MercadoLibre

Envíos Gratis en el día Compre Resma Papel Carta Hammermill en cuotas sin interés! Conozca nuestras increíbles ofertas y promociones en millones de productos. ... Saltar al contenido Comentar sobre accesibilidad Mercado Libre Venezuela - Donde comprar y vender de todo. Ingresa lo que quieras encontrar. Categorías. ... Resma De Papel Oficio ...

Read More

Papel Hammermill, papel de impresora reciclado 30% Great

Papel Hammermill, papel de impresora reciclado 30% Great Blanco, papel 8.5 x 11, tamaño carta, 20 lb, 92 brillante, 3 resmas / 1,500 hojas (086820C) Papel libre de ácido Marca: Hammermill 4.7 4.7 de 5 estrellas 22,122 calificaciones

Read More

Resmas Papel Carta Hammermill MercadoLibre

Envíos Gratis en el día Compre Resmas Papel Carta Hammermill en cuotas sin interés! Conozca nuestras increíbles ofertas y promociones en millones de productos. ... Saltar al contenido Comentar sobre accesibilidad Mercado Libre Venezuela - Donde comprar y vender de todo. Ingresa lo que quieras encontrar. ... Caja De Resma De Papel Carta ...

Read More