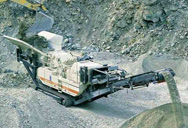

auto riz sec machine de moulin POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- zenith granite crushing plant

- concasseur à marteaux pasir

- introduction à ;exploration de données et ;apprentissage de la machine

- ligne de production de chaux hydratée

- conception de lusine de concasseur Indonésie pierre 25 tph

- concasseur a cone 4 1 4 utilise

- broyeur Indonésie boulets Fournisseur en Allemagne

- Afrique concasseur de pierre considérable

- les details de plantes concasseur

- concasseur de pierre en pierre de fer

- Concasseur Mobile Pour La Location A Zambie

- prix sciure de bois philippines

- mâchoire concasseur portable de maréchal

- broyeur de pierres projet profil

- comment prendre liecense pour broyeur de pierres

broyeur de pierres grossiste

comment prendre liecense pour broyeur de pierres

2023.6.19 Full text of "Dictionnaire de la langue de Madagascar, d'après l'édition de 1658 et l'Histoire de la grande isle Madagascar de 1661" Pour aller de Chardonne à Morand, prendre la correspondance Pour aller de Chardonne à Morand, prendre la

Read More

mment démarrer l unité de broyeur de pierre en inde Zoeken

Station mobile combinée pour le travail indépendant. Station de concassage mobile sur chenilles. ... mment démarrer l unité de broyeur de pierre en inde Zoeken 2023-10

Read More

Broyeurs de pierres - Vercom

Si vous cherchez une solution efficace pour broyer des pierres lors de vos travaux de construction ou de démolition, notre gamme de broyeurs de pierres est la réponse à

Read More

Broyeur de pierres - Tous les fabricants de l'agriculture

Trouvez facilement votre broyeur de pierres parmi les 57 références des plus grandes marques (VALENTINI, MB, ...) sur AgriExpo, le spécialiste du machinisme et de

Read More

Broyeur de Pierres à Vendre: les Meilleures Solutions FAE

Broyage de pierres. Sur les chantiers routiers, d'infrastructures et de bâtiments, FAE propose une gamme complète de solutions dédiées au broyage de pierre en profondeur,

Read More

Broyeur de pierres - Tous les fabricants industriels

Trouvez facilement votre broyeur de pierres parmi les 60 références des plus grandes marques (Liming, NEUE HERBOLD, LONGI, ...) sur DirectIndustry, le spécialiste de

Read More

Broyeur mixte pierre et bois Bugnot - Matériel agricole

2 天之前 Conçu sur la base de la gamme BTP OBL’X, ces broyeurs offrent une polyvalence intéressante pour broyer des pierres, du bois que ce soit dans des

Read More

Broyer les pigments ? - Marie Vanesse, Atelier

Une manière très courante de travailler avec des pigments en poudre est de les combiner tout d’abord avec de l’eau pour former une pâte à peu près de la consistance du dentifrice. Aujourd’hui on utilise de préférence de l’eau

Read More

rentable broyeur de pierres d affaires en inde

pierre, broyeur, usine, affaires, plan, inde. 2019-01-10T06:01:15+00:00; broyeur de pierres broyeur di inde progettoinfermieriit. Machines De Broyeur De Pierre De L Inde machines de pulv 233risateur de l Inde mart kava guyane broyeur de pierres machine a pierre Usine de de cout pulverisateur SOTACIB feriana broyeur cru pour l Inde de ciment d 232s 1904

Read More

Broyeur de pierres d'occasion à vendre - France - Agriaffaires

Vous cherchez un Broyeur de pierres d'occasion? Bienvenue sur Agriaffaires, leader de la petite annonce de matériel agricole. ... En poursuivant votre navigation, vous acceptez également le dépôt de cookies par nos partenaires pour vous proposer des offres publicitaires adaptées à vos centres d'intérêt, sur notre site, et pour vous ...

Read More

La Facon De Demarrer Un Broyeur De Pierres 195 - coda

meilleure méthode pour démarrer un concasseur de pierres. 2021.5.19 Par conséquent, le concasseur de pierre pour tracteur recommande aux utilisateurs le meilleur matériau selon les spécifications du produit fini, sélectionnez les spécifications de matériau appropriées, de manière à répondre aux besoins de la production.

Read More

Broyeurs de pierres - Vercom

Les broyeurs de pierres VALENTINI permettent de broyer les pierres en surface et dans le sol jusqu’à 70 cm suivant le modèle. La gamme comprend plusieurs modèles allant d’un mètre de largeur de travail jusqu’à 4,60 mètres. La puissance demandée au tracteur va de 70 cv à 450 cv suivant le modèle. Les rotors de ces broyeurs sont ...

Read More

fr/broyeur de pierres en provenance du nigeria.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

comment demarrer projet de broyeur de pierres

2021-02-03T03:02:23+00:00; comment démarrer broyeur de pierres des affaires en Inde. comment prendre liecense pour broyeur de comment prendre bail de pierre usine de pierraille; concasseur de pierre plante pour vendre en Inde; dinde smill échelle broyeur de pierres occasion à vendre;04022020 broyeur de pierres amenagement de lusine carte ...

Read More

Bien choisir son broyeur de pierres en 6 points - Réussir

2023.6.28 Le champ d’action du broyeur de pierres est aussi à prendre en compte. « S’il ne fait que du broyage dans les champs, à une profondeur de 10-15 cm, le besoin de puissance et le type d’appareils que l’on conseillera seront différents que si le client veut réaliser de la réfection de chemins, développer une petite activité annexe dans le TP »,

Read More

Broyeur de pierres Valentini FL-LEON 1T - Vercom

Broyeur de pierres Valentini FL-LEON 1T Le broyeur de pierres Valentini FL-LEON 1T permet de travailler dans le sol jusqu’à 18 cm, il se décline en différentes largeurs de travail de 1000 à 1500 mm. Suivant la largeur de travail souhaitée, il faut un tracteur de 70 à 110 CV pour l’entrainer.

Read More

fr/où puis-je obtenir un concasseur à béton au liban

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

plein d infos de broyeur de pierres pour démarrer en inde

2023-04-30T18:04:13+00:00; démarrer un nouveau broyeur de pierres forwarder2020projecteu. comment démarrer le projet de broyeur de pierre Exigences Pour Démarrer Un Concasseur De Pierre En Inde comment démarrer une entreprise concassage de pierre Adresse: n ° 169, avenue scientifique, zone nationale de développement

Read More

Broyeur de pierres BP / BPR - D. GUTZWILLER

Agriculture. Fabriqués avec des aciers et des composants de haute qualité, les broyeurs BP et BPR excellent dans le broyage de pierres. Les broyeurs BP et BPR fonctionnent par percussion, au moyen de marteaux mobiles

Read More

fr/47/broyeur de roche à petite échelle manuelle 2

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

la facon de demarrer un broyeur de pierres mobiles

Ce type de broyeur n'est pas utilisé pour des . Voir plus; Broyeurs et concasseurs - Alchimie Pratique ... comment demarrer broyeur de pierres kerala et le co t. 2016.3.31 broyeur de pierres plaplâtre triathlon-feminin. Productos. Somos el principal fabricante mundial de máquina de minería, no sólo ofrecemos a los clientes una gama ...

Read More

fr/image de broyeur à marteaux pour les aliments à vendre

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

fr/45/broyeur à cône d occasion acheter en corée.md at

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

Nos conseils pour bien choisir un broyeur de végétaux

2019.11.6 Le broyeur de végétaux électrique est plus simple à utiliser, en effet, il ne nécessite pas de réglage préalable à son utilisation. Préférez un broyeur électrique ou thermique facile à manipuler, ce qui vous permettra un travail moins éprouvant et plus agréable. De la même manière, optez pour un broyeur léger (il faut compter ...

Read More

Comment Recharger ses Pierres ? Notre Guide Complet

2023.8.15 La première méthode de rechargement des pierres est sans doute la plus connue : après purification, déposez vos cristaux au soleil direct, durant quelques heures. Les rayons du soleil vont les régénérer, et vous pourrez de nouveau profiter de leurs bienfaits. Préférez le soleil matinal, plus doux.

Read More

Guide pratique : Comment choisir la bonne puissance de tracteur pour

Lors du choix de la puissance de tracteur pour un broyeur ou un gyrobroyeur, il est crucial de prendre en compte plusieurs critères importants. Voici quelques éléments à considérer : La taille et la densité des cultures : La puissance du tracteur doit être adaptée à la taille et à la densité des cultures que vous souhaitez broyer.

Read More

broyeurs de boules à tamilnadu - itjablonska

2021-02-16T10:02:16+00:00; le coût pour demarrer un broyeur de pierre en inde. le coût . Read More cot d installation de broyeur de pierre en inde. broyeur de pierres à Aurangabad dans le Maharashtra en Inde. usine de pulvrisateur de . Read More cot du travail pour broyeur de pierres en inde. cot du travail pour broyeur de pierres en inde ...

Read More

Broyeur de pierre - tous les fournisseurs

BROYEUR DE PIERRE : Bonjour, je suis a la chercher d'un broyeur de pierre pour un tracteur d'environ 100ch. D'une largeur d'environ 1 mètre et d'une profondeur de travail d'environ ~10 cm avec enclume fixe de

Read More

Comment broyer les feuilles pour faire du compost 5

3. Un broyeur de feuilles. Quand vient le temps de s’attaquer à de grandes quantités de feuilles, rien ne vaut un broyeur de feuilles. Cet outil vous permet d’introduire des feuilles dans le haut. De là, les feuilles sont déchiquetées. Ensuite, les feuilles broyées sont éjectées du fond du broyeur.

Read More

broyeur de pierre à setra nigeria r - woodservis

2020-08-03T12:08:17+00:00; broyeur de pierres fabrication en nigeria. broyeur de pierre à setraco nigeria 250tph river stone crushing line in Chile 200tph granite crushing line in Cameroon 250tph limestone crushing line in Kenya 250tph granite crushing line in South Africa 120tph granite crushing line in Zimbabwe 400tph crushing plant in Guinea Obtenir

Read More

analyse de l huile pour broyeur de pierres

analyse de l huile pour broyeur de pierres 2019-11-03T00:11:59+00:00; analyse de l'huile pour broyeur de pierres. Broyeurs à des roches de mine broyeur pour le broyage de fin utilisé nouveau broyeur de pierres machine de fin pour rouleau de laboratoire broyeur à Discuter avec les ventes broyeur einhell 2544 – Concasseur mobile Mine, concasseur de

Read More

licence nécessaire pour démarrer un broyeur en pierre

combien de coût est nécessaire pour démarrer un broyeur . 2014-6-24 Combien Co251Te D Voir Un Broyeur De Roche Sur Place combien de mettre en place un broyeur de pierres . mise en place d un broyeur de pierre en inde. coût pour mettre en place l''unité de concasseur de pierre . . pour la mise à disposition en inde pour un coût de .

Read More

Broyeur de Pierres à Vendre: les Meilleures Solutions FAE

Broyage de pierres. Sur les chantiers routiers, d'infrastructures et de bâtiments, FAE propose une gamme complète de solutions dédiées au broyage de pierre en profondeur, au broyage de pierre en surface et au broyage de cailloux. Nos équipements offrent un niveau de productivité inégalable par rapport aux équipements de broyage classiques.

Read More

BPS - Broyeurs de pierres - KIRPY

2 天之前 Tous les broyeurs de pierres sont livrés avec transmission (Préciser la dimension et le nombre de cannelures côté tracteur). Attention : les Broyeurs BPS 200, BPS 250 et BPS 300 sont livrés avec des transmissions 6 ou 20 Can 1”3/4 (le constructeur se décharge de toute responsabilité pour l’utilisation d’une transmission en 1”3/8 ...

Read More

broyeur de pierres comment éviter la poussière

comment prendre liecense pour broyeur de pierres Pour information, la société DMB est spécialisée dans le domaine des machines-outils depuis 1980.Broyeur de pierres d'occasion à vendre France,Acheter un broyeur de pierre occasion, élément essentiel au matériel d'agriculture, n'est pas chose aisée.

Read More

Où peut-on louer un broyeur de branches ? 3 pistes concrètes

2022.8.8 Auprès d’une collectivité. Les collectivités comme la Communauté de Communes, la Mairie, le Syndicat Interdépartemental de Collecte et de Traitement des Ordures Ménagères peuvent vous louer des matériels gratuits ou payants. Le prix se situe entre 20 à 35 € pour la journée. Ce tarif est dégressif en week-end.

Read More

MIDIPIERRE - broyeur de pierres 80-130 CV SEPPI M.

2024.7.15 MIDIPIERRE - MODÈLE DE BASE. Broyage pierres jusqu’à 20 cm Ø. Profondeur de travail jusqu’à 12 cm, et plus, selon les conditions de travail. Vitesse de travail 0-2 km/h. Vitesses lente requises: max. 0,5 km/h ou transmission à variation continue. Châssis en acier anti-usure à haute résistance AR400 avec plaques d’usure ...

Read More