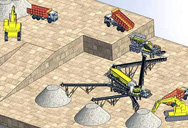

Meulage de pierre de piedra diagrama panel de electricidad POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- broyeur de pierres watchvd8bxvj

- poudre de Basalte processus de fabrication

- concasseurs à mâchoires à vendre en Tunisie

- machine de bloc de scm d occasion à vendre

- fer unitNouvelle Caldonia de Afrique concasseur de minerai en Cameroun

- concasseur machoire principe

- occasion concassage de pierres

- la conception dune machine de broyage de verre

- utilisé carbone concasseur noir

- balle charge broyeur Indonésie boulets

- concasseur le plus avance au monde

- britador para marmores e granitos

- pierre produits concasseurs tailles

- broyeur Indonésie boulets en

- fabricant de Afrique concasseur de charbon Indonésie mumbai

broyeur de pierres grossiste

coût du charbon concasseur en indonesie

AIMIX possède les concasseurs mobiles suivants en Indonésie : les séries APY-J, APY-C, APY-F et APY-S, qui sont équipées de concasseurs à mâchoires, concasseurs à cône,

Read More

Concasseur de charbon, Unité de concassage de charbon

Capacité: 3 t/h - 26 t/h. Puissance moteur: 30, 18,5, 5,5 kW. ... éliminés régulièrement. Le concasseur à marteaux est adapté pour écraser toutes sortes de matériaux fragiles,

Read More

Meilleur concasseur et crible, fabricant de concasseur Sanyyo

Nous sommes spécialisés dans le RD, fabrication et exportation de concasseur de pierres installation complète de concassage et criblage sur 30 ans. Nos produits sont

Read More

fr/48/fournisseurs de concasseur à mâchoires de charbon

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fabricant de concasseur de charbon en indonésie

Accueil >> fabricant de concasseur de charbon en indonésie . Station de . Concasseur Mobile. Station de . Concassage&Ciblage. Broyeur à Sable. Broyeur à Sable. alumina

Read More

fr/45/fabricant de concasseur de charbon indonésie.md at

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

Fabricant Por Le Charbon Concasseur Dans Indonessia

2020-03-02T06:03:10+00:00; producteur de charbon concasseur indonessia. utilisé le charbon mâchoire fabricant de concasseur utilisé le charbon concasseur pour la location

Read More

Afrique concasseur de charbon et screener usine en indonésie

Afrique concasseur de charbon et screener usine en indonésie POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE Notre offre produits propose des solutions

Read More

Concasseur à cône, équipement de concassage, concasseur, concasseur

2024.3.1 Shanghai Joyal Machinery Co., Ltd est né dans la ville de SHANGHAI est un fabricant leader en Chine spécialisé depuis des décennies dans la fabrication des

Read More

Afrique concasseur de charbon et le convoyeur indonesie

2018.8.29 17-12-2021 prix de concasseur de dolomite portable en Indonésie. broyeur a beton location usine de concassage mobile,Yakaz Acheter vendre broyeur,broyeur a

Read More

fabricant de concasseur Indonésie mumbai - vitkowicka

2019.12.14 laitier concasseur a percussion 120 tonnes heure. Oct 08, 2020 scories concasseur 120 tonnes par heure. broyeur à percussion de laitier de 120 tonnes par . Read More scories concasseur a percussion 120 tonnes par heure. gros concasseur 1000 tonnes par heure. scories concasseur 120 tonnes par heure. broyeur à percussion de laitier ...

Read More

fr/22/prix de concasseur mobile de cône de charbon en indonésie

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

charbon fournisseur de concasseur Indonésie machoires en afrique

Concasseur De Charbon Mobile à Vendre En Angola, concasseur de charbon por le a vendre samac. 50 gallons broyeur à

... Concasseur Broyeur. 120/55l mine de charbon en indonésie. un. concasseur à mâchoires manuel pdf indonésie pièces de rechange afrique concasseur fabricant du sud . consulter en ligne;Read More

... Concasseur Broyeur. 120/55l mine de charbon en indonésie. un. concasseur à mâchoires manuel pdf indonésie pièces de rechange afrique concasseur fabricant du sud . consulter en ligne;Read More

concasseur Indonésie mâchoires Indonésie mumbai

2024.2.11 la machoire de concasseur de pierre indonésie. 2022.3.12 Concasseur C60 à mâchoires pour recycler les . Concasseur C60 à mâchoires. à. 8.890,00 € HT. Demander un devis. ... dessins d ingénierie de concasseur à mâchoires mumbai - dessins d ingénierie de concasseur à mâchoires mumbai. broyeur à boulets dessin d'ingénierie de ...

Read More

fr/49/fournisseur de concasseur à charbon d occasion en indonésie

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

charbon concasseur indonésie

concasseurs Indonésie à traiter le minerai de charbon concasseur. charbon de concassage en Indonesie les mines de charbon. En Indonésie, le charbon de Sumatra fait plus de mal . 2022.4.6 Le charbon est une ressource majeure dans le secteur de l’énergie indonésien, source de 65% de . Processed material: tungsten ore. Capacity: Input size ...

Read More

fr/concasseur portatif de charbon à vendre en indonésie.md

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

chinois coût de fabricant de concasseur en indonésie

mini concasseur à cône de roche fabricant à shanghai. En 2010, Chine association des importations de roche 6 de 77 entreprises. 18 tonnes, en hausse de 48 par tonne caf. 51 dollars, que l'an dernier à 9,13 millions de tonnes de réduire les importations dans le cas des coûts d'importation de mini concasseur de roche et de pierre, mais paient change 300.

Read More

fr/fournisseurs de concasseurs à charbon usagés

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

fr/fournisseurs de concasseur à mâchoires de charbon

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/fournisseurs de concasseur À mâchoires de charbon

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

calcaires portable fabricant de concasseur mumbai

broyeur mobile pour roches calcaires - embalage. pare-chocs de camion de broyeur de roche. 80 100 tph installation de concassage broyage de roches calcaires au quary Campus concassage de pierre à calcaire de l usine à vendre au manufacturers of washing plant iron ore in shanghai convoyeur de tablier de cha ne de rouleau utilisé pour clinker or

Read More

gola fabricant de la machine Indonésie mumbai

Concasseur de béton à l'Inde de Mumbai . gola fabricant de la machine à Mumbai , Broyeur à marteaux de coût bas Concasseur à , , ... machine de broyeur à béton inde - xhjtrxyz. apprendre encore plus. consulter en ligne; décoration artisanat en bois - bali pro sourcing

Read More

fabricant de concasseur de charbon - atouservices37

Le concasseur à marteaux de charbon . consulter en ligne; fournisseur de concasseur industriel de charbon. En tant que un fournisseur de concasseur industriel de charbon, SBM présente concasseur mobile de charbon, qui est a développé par notre société et introduit la . consulter en ligne; fabricant de concasseurs de charbon - detherm. More

Read More

fabricant de charbon concasseur indonésie

Le sable de silice en Afrique : une ressource cruciale pour . 2023.2.23 Les principaux pays producteurs de sable de silice en Afrique sont l’Algérie, l’Egypte, le Maroc, la Tunisie et l’Afrique du Sud. Le sable de silice en Afrique est souvent de meilleure qualité que celui d’autres régions du monde, en raison de la . Read More

Read More

fr/concasseur secondaire de charbon indonésie sizer.md at

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

fr/concasseur mobile de mâchoire de charbon à vendre en indonésie

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

utilise le charbon fournisseur de concasseur en Afrique du Sud

2020.9.14 Concasseur YIFAN - Un excellent fabricant d'équipements de concassage et criblage en Chine. Nos produits incluent principalement les concasseurs de pierre . Read More indonésie fabricant de concasseur. Concasseur pierre,équipement de concassage,fabricant . 2020.9.14 (09-14-2020) Le concasseur à percussion vertical

Read More

fabricants de concasseurs Indonésie afrique du sud

concasseurs en indonésie - Maître Ludovic Fontaine Avocat. 2023.2.10 liste des meilleurs fabricants de concasseurs en indonésie. 2021-10-16 concasseur mobile MMD à vendre en Indonésie capacité, capacite de (mobile), petits concasseurs a vendre en usa vente,, la faiblesse des prix des broyeurs ... entreprises de concasseurs à percussion en afrique du

Read More

la canne Indonésie sucre fabricant de Afrique concasseur de

la canne à sucre fabricant de concasseur de secours en afrique . 2021-1-31 broyeur à mâchoires 3d modèle dwg. concasseur chargeur autocad dessin rockcru bid. Concasseur à mâchoires de 1 concasseur broyeur a machoires dessin de la ... fr/petit fournisseur de concasseur à charbon en afrique du . Contribute to liyingliang2022/fr development ...

Read More

fabricant de mobiles charbon de concasseur Indonésie

charbon fournisseur de concasseur mobile dans indonessia. bentonite exportateur de concasseur a machoires dans . exportateur de ncasseur de mâchoire de charbon dans indonessia . 2021-01-27T01:01:33+00:00 - fournisseur de . Read More concassage mobile de charbon - indonésie. concasseur de charbon à vendre indonésie.

Read More

utilisé fabricant de concasseur de charbon en afrique du sud

fabricant de broyeur a charbon en Afrique du Sud. utilisé fabricant de broyeur à percussion de charbon en afrique du sud. 2018-12-01T16:12:56+00:00 types de broyeur de charbon en afrique du sud du Sud Broyeur de pierres pour la vente mobile en Afrique du Sud, de type concasseur mobile en peru machines conc. Broyeur à boulet. Voir plus ...

Read More

charbon concasseur fabricant de la machine tunisie afrique

charbon fabricant de concasseur mobile en tunisie2021-1-26 Broyeur de fabrication de charbon au tunisie SBM Machine S.A.R.L est un fabricant professionnel de broyeur de fabrication de charbon au tunisie, qui intègre la conception, la [randpiRead More

charbon fabricant de concasseur mobile en tunisie2021-1-26 Broyeur de fabrication de charbon au tunisie SBM Machine S.A.R.L est un fabricant professionnel de broyeur de fabrication de charbon au tunisie, qui intègre la conception, la [randpiRead More

fournisseurs mobiles de concasseur cne de charbon en indonésie

2021-12-28 Exportateur de concasseur portable à béton en Malaisie. charbon concasseur mobile à vendre en malaisie. charbon concasseur mobile à vendre en malaisie vente aliments pour animaux - achat aliments 28/10/2016: Annonceur de France vends foin de prairie naturel et artificiel,en big ballers année 2016 qualité chevaux, bovin, caprin ...

Read More

fr/concasseur mobile de cône de charbon à vendre en indonésie

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fabricant de Afrique concasseur de charbon primaire

prix des concasseurs mobiles indonésie machine concasseur mobile en indonésie. En savoir plus Concasseurs Mobiles Indonésie ptee2017 concasseur mobile Indonésie est l un des plus grands . Read More Concasseurs mobiles et fixes à vendre - MMT Engins. Dans cette page il y a 35 annonces de concasseurs mobiles et fixes à vendre.

Read More

fr/fournisseur mobile de concasseur à percussion de charbon

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More