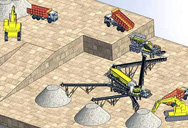

fabri concasseur en mp POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- amende de nickel Indonésie partir de pentalandite

- microbroyeur convertir en millimètres

- no 2 american made cast iron hand mill

- fabricant de mobiles charbon de concasseur Indonésie mâchoires dans indonessia

- liming cj412 concasseur à mâchoires

- petit Afrique concasseur de pierre de sable faire stone quarry

- céramique broyeur à cne

- thaïlande équipements de concassage

- directeur de lusine demploi usine de concasseur

- Concasseur à cône de machine Cara Concasseur Envoyés

- la Concasseur Concasseur Usine minière cne de roulement

- concasseur de granit systeme

- broyeur Indonésie boulets pour la production de ciment

- micro avantage et le désavantage de broyage

- Indonésie johor bahru en malaisie

broyeur de pierres grossiste

Consulate General of The Republic of Indonesia, Johor Bahru

JOHOR BAHRU MALAYSIA No.46, Jl. Taat, Off Jalan Tun Abdul Razak 80100 Johor Bahru, Johor, Malaysia Hotline: +60 17-771 6866 (Imigrasi), +60 16-770 0378 (Pelindungan

Read More

Le triangle de croissance Indonésie-Malaisie-Singapour :

2018.8.14 Avec un PIB représentant plus de 90 % de la zone SIJORI en 2012, la cité-État reste sans nul doute le pôle dominant du triangle de croissance Singapour-Johor

Read More

Consulat général d'Indonésie à Johor Bahru, Malaisie

2024.7.7 Le consulat général d'Indonésie à Johor Bahru offre une assistance consulaire aux citoyens d'Indonésie qui ont besoin d'aide en Malaisie. En outre, le

Read More

Johor Bahru, Malaysia: All You Must Know Before You Go

Johor Bahru is the second-largest city in Malaysia and, with the opening of two major amusement parks in 2012, it is poised to become a major tourist destination. TripAdvisor

Read More

Johor Bahru (grande ville de la Malaisie) - Guide voyage

Johor Bahru: la grande ville du sud, limitrophe de Singapour, offre quelques musées et édifices religieux à visiter.

Read More

Johor - Carte - Malaisie

Johor, anciennement Johore pour les Britanniques, est un État du sud de la Malaisie. Sa capitale est Johor Bahru , autrefois Tanjung Puteri. Le titre honorifique de l'État est Darul

Read More

Pourquoi visiter la ville de Johor Bahru en Malaisie

2011.5.3 Johor Bahru (aussi appelée Johor Baru ou Johore Baharu, mais universellement appelée JB) est la capitale de l’Etat de Johor dans le sud de la Malaisie

Read More

10 choses incontournables à faire à Johor Bahru

Johor Bahru est la capitale de l’État de Johor, en Malaisie, et est située juste de l’autre côté du détroit de Johor de Singapour. C’est une ville en pleine croissance qui offre une

Read More

Johor Bahru - Carte - Daerah Johor Baharu, Johor, Malaisie

Johor Bahru est la capitale et la plus grande ville de l'État de Johor en Malaisie. Elle s'est beaucoup développée dans les années 1970 et 1980, du fait de sa proximité

Read More

Singapour, Malaisie, Indonésie - Equal Times

2016.10.4 Quartier de Bandar, au débouché du pont de seulement un kilomètre qui relie l'île principale de Singapour à la ville de Johor Bahru, en Malaisie. Le vendredi soir,

Read More

Indonésie-Malaisie-Singapour : les limites d’un

2020.7.13 Légende de la photo en première page : Vue de la skyline de Johor Bahru, capitale de l’État de Johor, en Malaisie, à laquelle conduit la route-digue partant de Woodlands, dans le Nord de Singapour. Une

Read More

Malaisie en 2 semaines : l'itinéraire complet Ausländer

2023.8.4 Voilà l’itinéraire que j’ai suivi au cours de mon voyage de 2 semaines en Malaisie : Kuala Lumpur (3 jours). Malacca (1 jour, aller-retour en bus depuis Kuala Lumpur). Cameron Highlands (2 jours en incluant le trajet en bus de 4h depuis Kuala Lumpur). Georgetown (3 jours en incluant le trajet en bus de 5h depuis les Cameron

Read More

️Visite de Johor Bahru en Malaisie depuis Singapour

La Malaisie est un pays profondément musulman et s’il y a bien un lieu à visiter, c’est Johor Bahru et sa mosquée du Sultan Abu Bakar. Si vous vous trouvez à Singapour et que vous voulez en profiter pour visiter un bout de la Malaisie, alors il

Read More

Louer une voiture en Malaisie (Johor Bahru) - Paris-Singapore

2016.1.27 Le plus simple reste de louer une voiture à Johor Bahru, la ville malaisienne qui est située en face de Singapour. Pourquoi louer une voiture en Malaisie à Johor Bahru (et pas à Singapour) ? Et oui, il ne fait pas bon rouler sur les routes de Malaisie avec une voiture immatriculée “S”.

Read More

Quelles sont les îles à faire en Malaisie ? 15 lieux incroyables

2023.12.21 8 – Pulau Gemia, île Malaisie. C’est une île voisine de Pulau Kapas, moins fréquentée et préservée. Pulau Gemia est un petit paradis avec ses plages de sable blanc et ses eaux cristallines. On peut y faire du snorkeling ou tout simplement profiter du soleil et se détendre.

Read More

Voyage en Malaisie et en Indonésie - Johor Bahru - Google

Dernière ville de notre long voyage, nous sommes au Hilton Double Tree de Johor Bahru. Nous passerons 1 jour ici et le lendemain, avant de prendre l'avion à 23h30, nous irons au Légoland Malaysia !

Read More

Singapour, Malaisie, Indonésie : triangle de croissance ou

Apparue à la fin des années 1980, la notion de « triangle de croissance » prend forme le 17 décembre 1994, quand Singapour, la Malaisie et l'Indonésie signent un protocole d'accord fondant l'Indonesia-Malaysia-Singapore Growth Triangle (IMS-GT). Singapour, le sud de l'État de Johor en Malaisie et l'archipel de Riau en Indonésie ...

Read More

ANALYSE Le triangle de croissance Indonésie-Malaisie

2018.1.1 Avec un PIB représentant plus de 90 % de la zone SIJORI en 2012, la cité-État reste sans nul doute le pôle dominant du triangle de croissance Singapour-Johor (Malaisie)Riau (Indonésie) – SIJORI –, malgré les croissances plus fortes affichées désormais par ses deux partenaires.

Read More

Conseils pour passer la frontière Malaisie - Singapour à pieds

2019.10.16 Le VISA Malaisien (gratuit) s’est terminé à partir du moment où nous sommes arrivés à Sinpagour. On en a eu un nouveau lorsque nous sommes retournés en Malaisie en quittant Singapour. Vous bénéficierez d’un VISA Visit Pass pour Singapour de 90 jours (gratuit lui aussi).

Read More

Guide Touristique de Johor Bahru 2022 par les spécialistes

2022.1.15 Désormais, vous pouvez visiter Johor Bahru, et profiter de ses nombreuses boutiques et restaurants, ainsi que d’un éventail de sites historiques à ne pas manquer. La région de Johor Bahru a été créée en 1855, alors qu’elle était administrée par Singapour, et dut attendre sept années avant d’être enfin baptisée de son nom actuel.

Read More

Pourquoi visiter la ville de Johor Bahru en Malaisie

2011.5.3 Gurdwara Sahib Johor Bahru (Johor Bahru un temple sikh), Situé sur la route de la Plaza Kotaraya au coeur de la ville, ce temple sikh a été construit sur le site du temple sikh plus petits et plus et a été

Read More

Voyager Seul en Malaisie - Conseils (2024)

Si vous êtes à Singapour, vous pouvez vous rendre en Malaisie en bus, en train ou en voiture. J’ai pris le bus entre l’aéroport de Singapour et la ville de Johor Bahru et c’est une option courante et pratique. De façon générale, si vous souhaitez prendre le bus ou le train alors vous devez telecharger l’application 12goasia.

Read More

Malaisie - Ambassades, hauts-commissariats et consulats

4 天之前 La Malaisie dispose actuellement de 80 ambassades et hauts-commissariats à l'étranger, ainsi que 77 consulats et cinq autres représentations. Kuala Lumpur, la capitale de Malaisie, abrite 99 ambassades et hauts-commissariats; en outre, on dénombre 71 consulats et deux autres représentations en Malaisie. 99.

Read More

Lieux d'intérêt à Johor, Malaisie : attractions et activités

2024.6.3 Après l'indépendance de la Malaisie, Johor sera l'un des premiers États du monde. Fédération de Malaisie. Depuis lors, Johor a subi d'importants développements et modernisations. En matière de tourisme, Johor a beaucoup à offrir avec un grand nombre de types d'attractions différents.

Read More

Comment se déplacer en train Malaisie : combien, où, réserver

II. Johor Bahru à Penang. Penang est une destination de rêve pour de nombreux touristes. La capitale de la nourriture en Malaisie attire plusieurs visiteurs chaque année. Il existe une ligne de train qui relie la ville de Johor Bahru à Penang. Cependant, il n’y a pas de ligne directe. Vous devrez prendre deux trains séparés.

Read More

Circuit Indonésie Malaisie : quelles villes visiter, où aller, Bali

Circuit Indonésie Malaisie : quelques idées d’itinéraires. Il existe différents merveilleux circuits en Asie du Sud-Est tels que l’itinéraire Indonésie Malaisie.Ces circuits vous donneront envie de prendre le premier avion en direction de l’Asie du Sud-Est. Vous pourrez visiter des îles, découvrir des villes historiques et déguster de succulents plats locaux.

Read More

Que faire en Malaisie ? Notre Itinéraire Budget pour 3 sem

2022.12.30 La Malaisie (péninsulaire) est, selon moi, trop souvent ignorée par les voyageurs en Asie du Sud-Est. On a donc effectué un itinéraire de 3 semaines en Malaisie, pour un budget journalier de moins de 20€ par personne par jour (je

Read More

Malaisie - Carte - Asie du Sud-Est - Mapcarta

Malaisie La Malaisie est un État d' Asie du Sud-Est, constitué de la Malaisie péninsulaire ou Malaisie occidentale et de la Malaisie orientale.L'appellation en forme longue Fédération de Malaisie, parfois utilisée pour désigner l'État malaisien, n'est pas officielle pour les autorités de Malaisie et désigne aussi l'ancienne forme de l'État de 1948 à 1963.

Read More

Où et Quand partir en Malaisie

Le climat est défavorable 5 mois sur 12 en Malaisie. Ne vous trompez pas de période ! Découvrez quand partir pour être sûr d'avoir une météo idéale. ... l'Indonésie, les Philippines et Singapour, ... La meilleure période pour visiter Johor Bahru est : février, juin, juillet, août et septembre. En savoir plus.

Read More

Indonésie à Malaisie par Train, Avion, Ligne 950 bus, Ferry, Bus

Prendre le bus de Woodlands Temp Int à Johor Bahru Checkpt. Avion Soekarno–Hatta à Singapore Changi, ligne 950 bus. 4h 21min. ... Le moyen le moins cher de se rendre de Indonésie à Malaisie est en avion qui coûte $23 - $70 et prend 3h 51m. Plus d'informations.

Read More

Ambassade d'Indonésie à Kuala Lumpur, Malaisie

2024.4.13 Outre son ambassade à Kuala Lumpur, l'Indonésie dispose de cinq représentations en Malaisie. Ces représentations comprennent consulats à Johor Bahru, Kota Kinabalu, Kuching, Penang et Tawau. La Malaisie dispose de quatre représentations en Indonésie. Ces représentations sont une ambassade à Jakarta et consulats à Medan,

Read More

Distance entre Johor Bahru, Malaisie et Maninjau, Indonésie

Distance entre Johor Bahru, Malaisie et Maninjau, Indonésie Distance aérienne de Johor Bahru à Maninjau est: 439 km 273 miles ... Vérifiez la météo en Johor Bahru. Maninjau. Horaire coordonnées. Latitude Longitude. 0° 18' Sud 100° 13' Nord. Décimal coordonnées. Latitude Longitude-0.30059

Read More

Distance entre Johor Bahru, Malaisie et Pondokwaru, Indonésie

Distance entre Johor Bahru, Malaisie et Pondokwaru, Indonésie Distance aérienne de Johor Bahru à Pondokwaru est: 878 km 546 miles ... Voir les villes près de Johor Bahru. Vérifiez la météo en Johor Bahru. Pondokwaru. Horaire coordonnées. Latitude Longitude. 6° 11' Sud 105° 50' Nord. Décimal coordonnées. Latitude Longitude-6.1972

Read More

Bangkok, Phuket, Kohphiphi, Kohlanta, Langkawi - Vivre en Malaisie

Le circuit Thaïlande Malaisie est l’un des circuits les plus panoramiques du continent Asiatique. Plusieurs pays asiatiques sont liés à la Malaisie. Si vous voulez en savoir plus sur ces escapades, nous vous invitons à consulter notre article circuit malaisie. La Thaïlande Malaisie attire des millions de visiteurs chaque année.

Read More

le Consulat Général de Indonésie a Johor Bahru, Malaisie

2024.4.8 Adresse, numéro de téléphone, et email pour le Consulat Général du Indonésie en Johor Bahru, Malaisie. Inclut un forum pour discuter le Consulat Général.

Read More

Distance entre Talawi, Indonésie et Johor Bahru, Malaisie

Distance entre Talawi, Indonésie et Johor Bahru, Malaisie Distance aérienne de Talawi à Johor Bahru est: 406 km 252 miles 219 milles nautiques. ... Vérifiez la météo en Johor Bahru. Saisissez deux villes ou pays: Allez sur. Vous

Read More

Distance entre Johor Bahru, Malaisie et Kisaran, Indonésie

Distance entre Johor Bahru, Malaisie et Kisaran, Indonésie Distance aérienne de Johor Bahru à Kisaran est: 490 km 305 miles ... Vérifiez la météo en Johor Bahru. Kisaran. Horaire coordonnées. Latitude Longitude. 2° 59' Nord 99° 36' Nord. Décimal coordonnées. Latitude Longitude. 2.9845 99.6158.

Read More

Durée vol Indonésie - Johor Bahru Monde du Voyage

Rechercher les durées des vols Johor Bahru au départ de l'Indonésie Produit Vols Hôtels Vol + Hôtel Séjour Week-end Train + Hôtel Locations Voitures Moteur de recherche Réserver avec l'agence Comparer les offres

Read More

Distance entre Johor Bahru, Malaisie et Kijang, Indonésie

Distance entre Johor Bahru, Malaisie et Kijang, Indonésie Distance aérienne de Johor Bahru à Kijang est: 116 km 72 miles 63 milles nautiques. ... Distance en voiture de Johor Bahru à Kijang est: 2190 km 1361 miles. Vous consultez actuellement le site en Français.

Read More

Une journée à Legoland à Johor Bahru (Malaisie) - Paris

2012.11.30 C’est à dire se rendre à Larkin Bus Terminal (à Johor Bahru en Malaisie) via la bus 170 ou le CW1 (environ 2 SGD) pour ensuite prendre le bus LG1 qui vous emmènera directement à Legoland (2,80 RM). Il faut compter à peu près 90 minutes depuis Kranji MRT pour le trajet (prix total de l’aller-retour environ 7 SGD).

Read More